Business

HOME | Business | Scrap Iron Processing

Scrap Iron Processing

Appropriate Sorting Process

Material Processing to Meet Our Customer's Needs

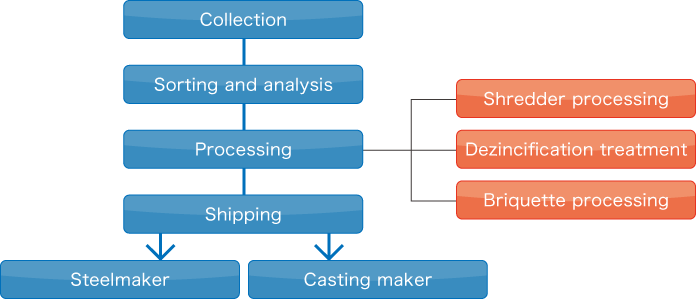

Iron Scrapping Process

Shredder processing

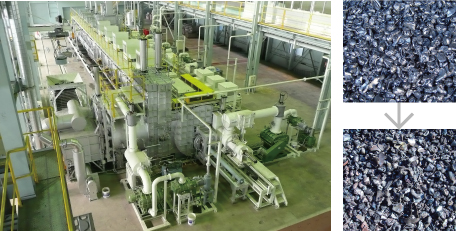

Steel sheet scrap generated in the automobile production process is shredded with a vertical grinder mill (VGM) or 1,250 hp shredder machine to produce shredded material with high bulk specific gravity. The shredded material is sorted by type, and then supplied to electric and blast furnace makers and casting makers as raw material.

Dezincification treatment

Our dezincification treatment device is revolutionary piece of equipment which utilizes the difference in steam pressure between iron and zinc. In a vacuum-processed furnace, galvanized steel sheet is heated to evaporate only zinc for isolation and recovery. In a vacuum-processed environment, zinc can be evaporated at a lower temperature than the boiling point of the material to facilitate energy saving. In addition, since it is processed in a vacuum-processed environment, iron and zinc are not oxidized. Consequently, zinc of high purity can be recovered. Iron from which zinc was isolated is used as high-quality recycled material.

Briquette processing system

HOEI METAL's briquette processing system recycles turning generated in the automobile production process, as well as disposed polishing scrap and iron powder. It then converts these into briquette products, which are used as raw material for steelmaking and casting. Particular attention is paid to product quality. By firing material after press-molding, machine oil and water can be almost completely removed, resulting in high-value added raw material for steelmaking and casting.

Headquarters Plant Scrap Iron Processing Equipment

| |

1 |

|---|---|

| |

2 |

| |

1 |

| |

1 |

![]() Production capacity

Production capacity

![]() VGM(500hp)

VGM(500hp)

5 tons/hour, production size: 30 mm to 50 mm

![]() Product line-up

Product line-up

Newly shredded material (various types), steel turning, burrs generated by forging

Akashi Plant Scrap Iron Processing Equipment

| |

1 |

|---|---|

| |

1 |

| |

2 |

| |

1 |

| 10 tons/hour, production size: 80 mm to 100 mm |

| 2 tons/hour, dezincification rate 99% |

|---|

| Newly shredded material (various types) Dezincification-processed shredded material Beryllium copper (degreasing treated) |

Obayashi Plant Scrap Iron Processing Equipment

| |

3 |

|---|---|

| |

1 |

| 3.5 to 5.5 tons/hour, production size: diameter 140 mm to height 150 mm |

|

| |

|---|

| Steel turning briquettes Iron turning briquettes Beryllium copper briquettes Polishing powder turning briquettes, etc. |